Pay in 3 prices shown are an example only. Total calculated at checkout.

Delivery within 2 - 5 working days

Free Delivery On Orders

Over £599.95 Ex-Vat

Need something quicker?

Contact us on 0300 303 4578

or email here!

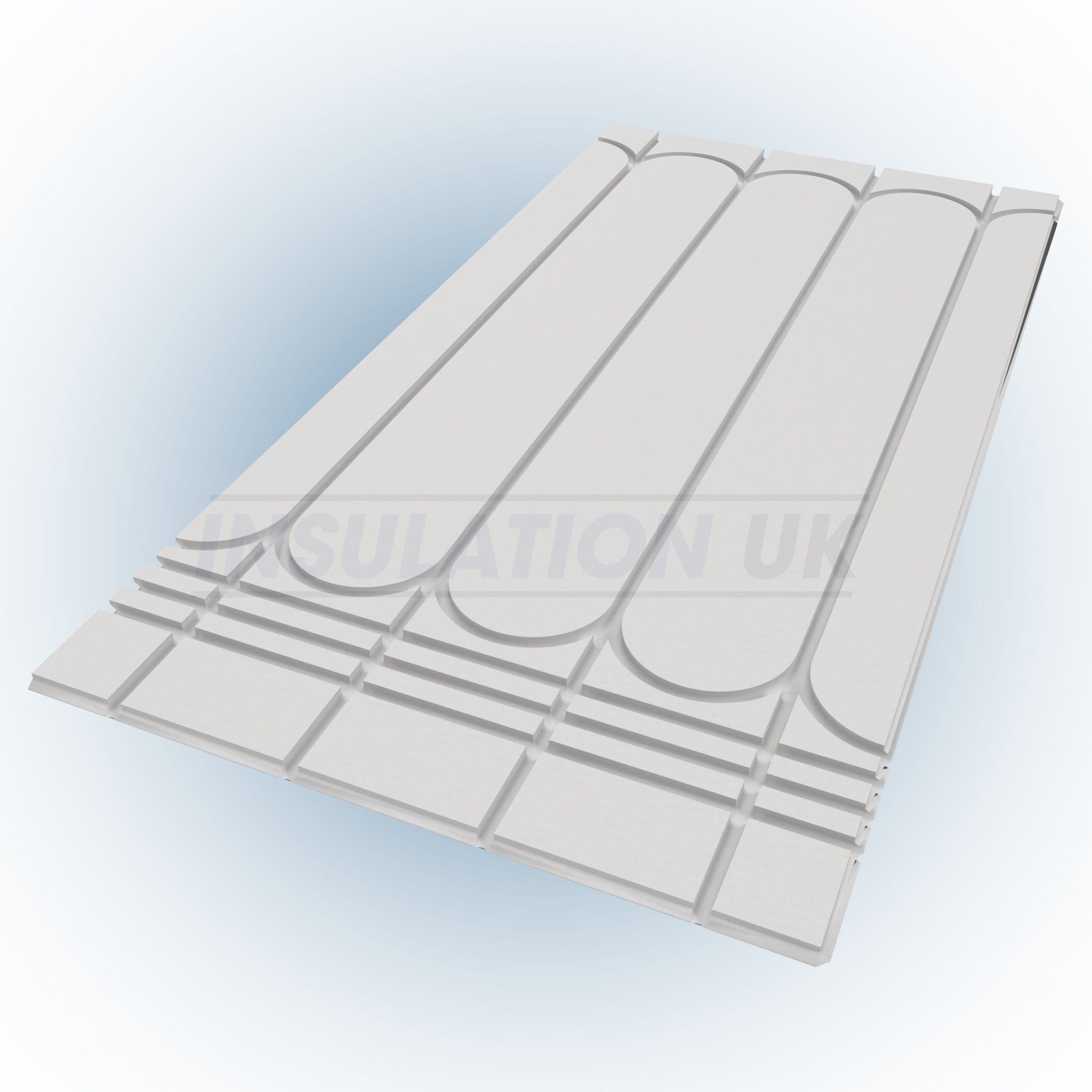

Tekwarm Gypsheet-R UFH Board

Innovative Heating Solution with Tekwarm Gypsheet-R UFH Board

Tekwarm Gypsheet-R UFH Board revolutionizes underfloor heating systems with its high-density gypsum fibre construction. Designed as a low-profile overlay system, it ensures minimal impact on floor heights while delivering superior thermal conductivity for an even spread of heat across the floor. Suitable for all types of floor finishes, its 18mm thickness and grooved face accommodate 12mm diameter underfloor heating pipes with radius returns as standard, making it an optimal choice for both new builds and retrofit installations.

Key Features:

- High Thermal Conductivity: Promotes an even heat distribution for enhanced floor heating efficiency.

- Low Profile Design: Its slim profile minimises changes to existing floor heights, seamlessly integrating with your space.

- Versatile Floor Compatibility: Compatible with all floor finishes, ensuring broad application across various projects.

- Easy Installation: Features tongue and groove edges for a tight fit, simplifying the installation process.

Technical Specifications:

| Specification | Details |

|---|---|

| Material | High-Density Gypsum Fibre |

| Board Size | 1200mm x 600mm x 18mm |

| Pipe Compatibility | 12mm Diameter UFH Pipes |

| Thermal Conductivity | High |

| Finish | Tongue & Groove on all edges |

| Installation Base | Suitable for suspended or solid floor constructions |

| Flooring Compatibility | All types including solid wood, laminate, tiles, carpet, vinyl |

| Additional Requirements | DPM as necessary, 6mm levelling compound or Tekwarm Construction Board for carpet/vinyl finishes |

Installation & Application

Tekwarm Gypsheet-R UFH Boards can be installed onto both suspended and solid floor constructions that are flat and level. For timber bases, panels should be fixed with Tekwarm mechanical fixings and washers, while boards laid directly onto concrete benefit from a bed of combed tile adhesive (S1 or equivalent). Depending on the substrate, mechanical fixings may also be required.

Finishing Touches

Solid wood flooring and laminate products require a suitable underlay per manufacturers' instructions, whereas flooring-grade tiles can be laid with a suitable combed tile adhesive layer. For carpet or vinyl finishes, an additional 6mm levelling compound or Tekwarm Construction Board is recommended for a smooth finish.

Benefits of Using Tekwarm Routed Insulation Boards for Underfloor Heating

Routed insulation boards are specialized panels designed for use in underfloor heating systems, featuring pre-cut channels for the easy installation of heating pipes or cables. Their design and material composition offer several benefits for both the efficiency of the heating system and the installation process. Below are the benefits of using routed insulation boards in underfloor heating systems, followed by guidance on their appropriate usage and finishing the floor after installation.

-

Improved Thermal Efficiency: Routed insulation boards are made from materials with high thermal resistance, which significantly reduces heat loss downwards. This ensures that more heat is directed upwards into the room, improving the efficiency of the underfloor heating system and potentially lowering energy costs.

-

Easy and Quick Pipe Installation: The pre-cut channels in the insulation boards are designed to precisely fit heating pipes or cables, making the installation process quicker and easier. This reduces the risk of installation errors and saves time for professionals and DIY installers alike.

-

Enhanced Structural Integrity: These boards provide a solid base for the heating system, supporting the weight of the floor finish and the foot traffic above. This can help in preventing cracks or damage to the heating elements and the floor covering.

-

Uniform Heat Distribution: The arrangement of the pipes or cables in the pre-cut channels helps in achieving a uniform distribution of heat across the floor surface, eliminating cold spots and ensuring a comfortable indoor environment.

-

Versatility: Routed insulation boards can be used with various types of underfloor heating systems (water-based or electric) and are compatible with many types of floor finishes, offering flexibility in design and use.

-

Noise Reduction: These boards can also offer acoustic benefits by dampening sounds, contributing to a quieter indoor environment, which is particularly beneficial in multi-story buildings.

When to Use Routed Insulation Boards

Routed insulation boards should be considered in the following scenarios:

- New Construction or Major Renovations: When accessibility to the subfloor is not an issue, and there's an opportunity to optimise energy efficiency from the outset.

- Rooms with High Heat Loss: Such as basements or rooms with large windows, where additional insulation can significantly improve thermal efficiency.

- When Uniform Heating is a Priority: In spaces where eliminating cold spots is essential for comfort and energy efficiency.

Finishing the Floor After Installing Underfloor Heating

After the underfloor heating system has been installed with routed insulation boards, the finishing process typically involves the following steps:

-

Secure the Heating Elements: Ensure that heating pipes or cables are securely fixed within the routed channels to prevent movement during the floor finishing process.

-

Conduct a System Test: Before laying the final floor covering, it's crucial to test the heating system to ensure it operates correctly.

-

Apply a Levelling Compound (if necessary): For certain types of floor finishes, applying a self-levelling compound or screed over the insulation boards and heating elements creates a smooth, level surface.

-

Install the Floor Finish: Depending on the chosen material (tiles, laminate, wood, etc.), the floor finish is then laid on top of the insulation boards. It's important to select a floor finish that is compatible with underfloor heating, ensuring it can withstand the heat output and allow efficient heat transfer.

-

Final System Check: Once the floor finish is installed, perform another test of the heating system to ensure everything functions as expected after the complete installation.

Downloads

| Order Value | Delivery Charge |

|---|---|

| Up to £200.00 ex-vat | £100.00 ex-vat |

| £200.00 - £599.95 ex-vat | £59.95 ex-vat |

| Above £599.95 ex-vat | Free Delivery |

| Weekend Delivery |

|---|

| Available upon request |

| Parcel Rates |

|---|

| Delivery charge may vary depending on quantity and volume of your order. |

| Pricing will be calculated during checkout. |

| Local Delivery Charge |

|---|

| Within 35 miles of Postcode S63 9BL - Up to £500.00 ex-vat |

| Delivery Charge £35.00 ex-vat |

| Collections |

|---|

| Please contact us to arrange collections Tel: 0300 303 4578 | Email: sales@insulationuk.co.uk |

Orders are only processed for delivery between 8.00am - 5.00pm Monday to Friday excluding bank holidays.

Moffett offload will be used for large bulky deliveries and only when agreed with you.

Please advise of any access issues on ordering.

Delivery is Kerbside only.

In the unlikely event that your delivery is not correct or damaged please notify us immediately and mark any issues on the delivery slip.

Where We Deliver

Product Delivery Times

The vast majority of our orders are dispatched within 3 working days, this can however be up to 5 working days, please contact us if you require something urgent.Speciality items may take up to 5-7 working days.

We will contact you with in 24/48hrs of your order been placed to confirm delivery times and dates.

Enter the width(m) and length(m) of your project below:

You may also like...

- Opens in a new window.